An Introduction to 3-Axis Waterjets and Abrasive Cutting

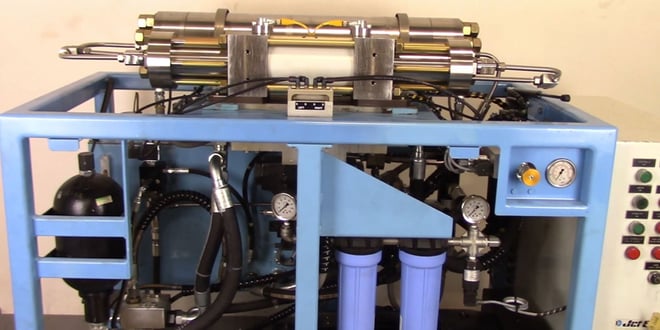

For many materials, waterjet cutting and abrasive cutting systems are used to cut in two dimensions – across the X and Y planes. In most of these applications, the Z axis the cutting head is mounted to remains fixed in the down (cutting) position ...

%20-%20Jet%20Edge%20Waterjets.png)

%20-%20Jet%20Edge%20Waterjets.png)