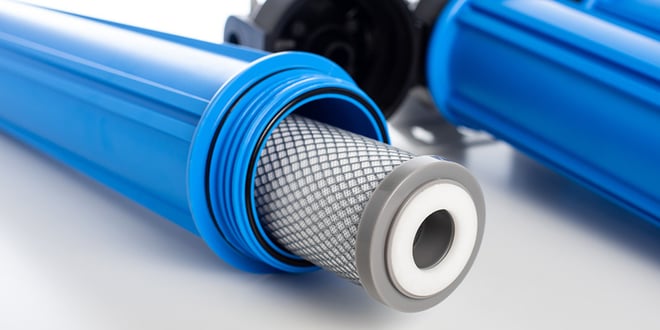

Water Quality and Water Jet Filter Replacement Best Practices

The water used in a waterjet cutting system serves two distinct and different purposes, the cutting process and hydraulics cooling. Poor water quality, as measured by the volume of suspended solids, reduces component life and increases the system’s ...

%20-%20Jet%20Edge%20Waterjets.png)

%20-%20Jet%20Edge%20Waterjets.png)