The water used in a waterjet cutting system serves two distinct and different purposes, the cutting process and hydraulics cooling. Poor water quality, as measured by the volume of suspended solids, reduces component life and increases the system’s maintenance requirements, both unnecessary and avoidable costs. By taking some simple steps to implement an optimized filter replacement practice you can maintain the high water quality you have achieved and increase the tool's performance and operational life. Let's explore the best practices for making this happen.

Water Treatment Options and Goals

The quality of the water you feed your waterjet affects its operation. Best practices include treating your input process water to control the following properties:

- Parts per million (ppm) of Total Dissolved Solids (TDS)

- PPM of silica

- pH level

Treating TDS and Silica Best Practices

Elevated levels of TDS in your process water cause accumulation of mineral deposits in supply lines, filters and nozzles. The effects include water pressure management issues, changes to nozzle geometries and premature component replacement. Excessive silica content abrades process water supply and cutting components, especially nozzles, reducing component life and potentially affecting cut quality.

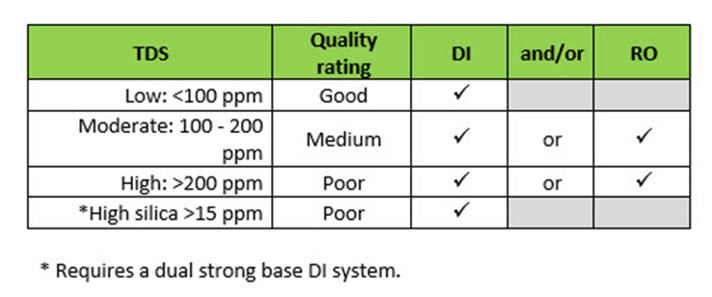

You have two excellent choices for reducing the TDS ppm of your process water: deionization (DI) and reverse osmosis (RO). The most severe cases require the use of both technologies. The following table illustrates the appropriate system or systems needed based on the ppm levels of your water.

Regardless of the treatment option selected, best practices recommend the following targets:

- TDS = 75 ppm

- Silica = 1 ppm

Water Temperature Management

Your water supply feeds both the cutting process and cooling of the hydraulics system. The hydraulic system uses heat exchangers to transfer hydraulic fluid heat from the hydraulic lines to the cooling water circulating in the heat exchanger. Best practices recommend cooler water for this application, ideally <70o F / 21.1o C.

The physical process of increasing the water pressure for cutting causes a rapid rise in water temperature inside the intensifier. If the water temperature rises too high, it reduces the lifespan of the intensifier's high-pressure seals and affects other components' useful lifespans. Hot supply water further exacerbates this problem. Best practice calls for input water temperatures of <70o F / 21.1o C.

Water Filters and Filtration

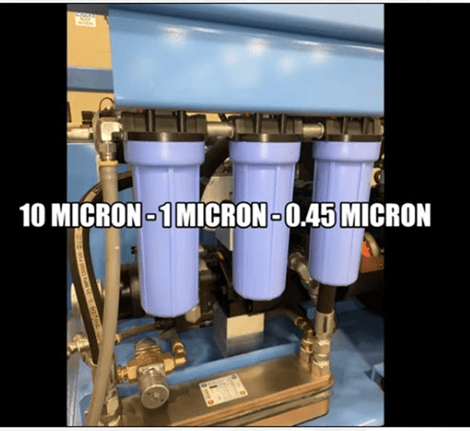

Depending on the pump model serving your intensifier, your waterjet may require one, two, or three water filters. The water filters complete the process water conditioning before it goes to the cutting nozzle. As illustrated below, these filters remove increasingly smaller particles from the process water, where the water flows from left to right.

Best practices for water filter replacement include changing them every 250 hours of tool operation or if the water pressure of the filtered water (output to the cutting nozzles) drops by 20 PSI compared to the input water pressure. The filter on the right pictured below caused a 20+ PSI drop in pressure for obvious reasons.

Safety is your first consideration when it is time to replace your waterjet's filters. Here are the steps to follow to replace your filters properly and safely.

- Turn off the input water supply and wait until the pressure gauge reads 0 PSI.

- Twist off the filter canister and remove the filter element.

- Properly dispose of the used filter element and insert the new one, observing proper orientation where applicable.

- Reinstall the canister, hand tightening only.

- Press the red air release button on top of each canister.

- Turn the supply water back on and record the water pressure.

Water Pressure Management

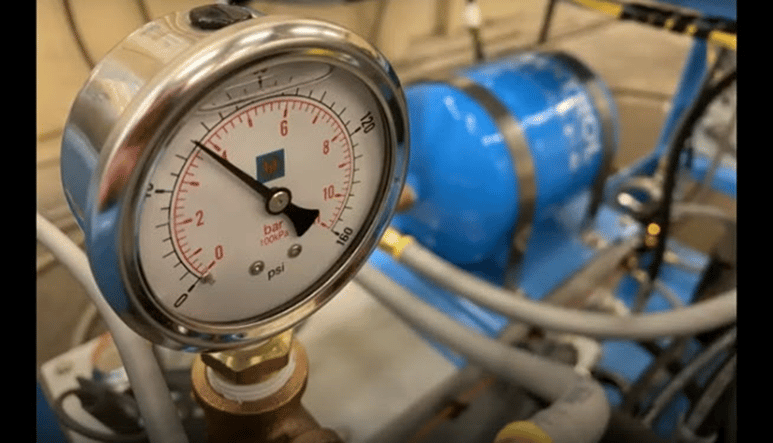

Water pressure gauges provide instant readings of real-time process water pressure, and you will have either one or two depending on your waterjet model. Aside from tracking the proper system pressure, you use the gauges as an indicator of filter health.

Single Gauge Use

In systems with a single gauge located downstream of the filters, record the water pressure every time you replace your filters. Keep a daily log of subsequent pressure readings, and when the pressure falls to 20 PSI below the new filter reading, it is time to replace your filters.

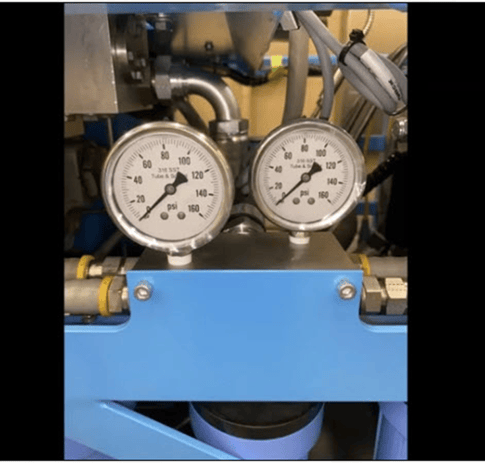

Dual Gauge Use

Systems with two gauges have a gauge on the input and output sides of the filter portion of your waterjet. The dual gauge arrangement greatly simplifies determining filter health. Located close together, you have immediate information about your filter's condition.

Water Pressure Management

Waterjet cutting systems are notable for their extremely high water pressure. However, your waterjet uses low or normal water pressures supporting other functions as your tool processes the material for your current job. To protect the low-pressure side of the tool from water pressure spikes, a water accumulator with an internal bladder buffers the low-pressure side. With the bladder inflated to 38 PSI +/- 10%, the accumulator functions as a shock absorber to dampen and dissipate damaging pressure spikes. An air fitting allows users to check and adjust the bladder's PSI. All that's required is a tire gauge and compressed air source.

Best Practice Targets

Let's wrap up with a summary of the best practice targets for your waterjet water quality and filter management processes:

- TDS: Less than 100ppm

- pH Value: 6.5 to 8.5

- Silica Target: Less than 1 ppm

- Water Supply Temp: 70F / 21C

- Replace Filter: 250 hours

Watch Our Video on Filter Replacement

To watch our water quality and filter replacement video, follow this link. To explore additional available resources, including maintenance training, case studies, technical bulletins, parts supply options and more visit our resource center.

Talk to Jet Edge

If you have questions about implementing water quality and filter replacement best practices, call us today at (763) 497-8700. We welcome the opportunity to answer your questions. If you would like help with a free water analysis just let us know.

Check Out Our Digital Brochure!

Since 1984, Jet Edge has been designing and manufacturing Ultra-High-Pressure Water jet technology that doesn't back down. Our systems are used around the world in a broad range of industries from the world's leading airlines, to automotive, aerospace and industrial manufacturers, and machine job shops.

To learn more about the Jet Edge difference, our water jet motion systems, pumps and much more, click the button "Download Brochure" to get it now!

%20-%20Jet%20Edge%20Waterjets.png)