Nature has been cutting and carving stone for billions of years. Nothing can resist the unrelenting force of water. Take the Grand Canyon, for example. Now that is a masterpiece of stone cutting with water. However, as a fabricator working with stone, you don't have the luxury of 6 million years, give or take a few millennia, to fulfill your client's order.

What Do Stone and Countertop Fabricators Cut Most Often?

There are three classifications of stone based on their formation method: sedimentary, igneous and metamorphic. Limestone, sandstone and slate are about the only sedimentary stones cut for commercial uses. Sedimentary rocks, in general, are too soft, stratified and fragile to cut.

Metamorphic and igneous stones commonly cut include soapstone, basalt, granite, and marble. These are much harder materials, hold detailed edges well and take a high polish, results impossible with most sedimentary stones.

The Unique Properties of Stone like Granite and Marble

Cutting a natural material presents different challenges than cutting a homogenous manufactured or engineered material. Here are a few:

- The stock material may arrive with different thicknesses across a single workpiece. This can present problems for CNC machines as the cutting tools try to follow the design parameters. For saws, varying thicknesses present changes in cut resistance that can change blade speed and cut quality.

- Stone often has inclusions of different minerals, each with different hardness. The inclusions may or may not be visible, making it challenging to work around them in setting up the cut. The effect of inclusions on the cutting tool is similar to varying thicknesses.

- Inclusions also increase scrap loss. Working around visible inclusions to reduce cutting issues results in lower material utilization rates and higher costs.

- Some popular stones are fragile or brittle, given their nature. Cutting with saws or CNC machine tools can lead to edge damage and material fractures.

Residential and Commercial Applications for Cut Stone

Cut stone has myriad applications in residential, commercial and industrial settings. The residential uses are likely familiar to most: highly polished granite countertops with sink cut-outs, countertops at various angles, tiles, waterfall edges, and one-piece sinks. Stone in both simple shapes and those with intricate inlays are commonly used for floor and wall coverings.

Commercial applications include structural uses like walls, decorative features like gargoyles, pediments, flutes, etc. Commercial uses also include flooring and wall finishes with stone tiles of diverse types, often featuring intricate designs using inlays and engravings.

While there are fewer industrial applications, one of the more interesting is surface plates. These are substantial blocks of granite with a top surface that is absolutely flat, to within 0.0115 mm per 2960 mm for a grade 0 plate. Granite is the material of choice because it is nearly immune to changes from humidity or temperature. According to Wikipedia,

Surface plates are a common tool in the manufacturing industry. They are often fitted with mounting points to be an integrated structural element of a machine such as a coordinate measuring machine, precision optical assembly, or other high precision scientific & industrial machines. Plates are typically square or rectangular, although they come in various shapes.

The Tools Used by Stone and Countertop Fabricators

When you pull a search for stone cutting tools, you get diamond blades, bridge saws, routers, polishers, waterjet cutting machines and combination machines as your result. The type of equipment used, is directly related to the types of cut you wish to perform and whether you are using CNC controlled machines or hand tools. While there are multiple methods for stone cutting, each method has its primary strength as well as its share of limitations.

Hand Tools

Hand tools are part of the trade, but only in a supporting role as the limitations speak for themselves: repeatability, speed, accuracy, fine finishes and safety. Students of archeology might argue the point after all, they built the Great Pyramids of Giza and megalithic structures like Machu Pichu constructed with simple bronze tools and thousands of workers over many years. Be that as it may, this fabrication approach has been relegated to the second team in today's world.

Bridge Saws

Bridge saws are a common machine tool used in the stone fabricators workshop. They are capable of simple, straight cuts but have difficulty when it comes to creating edge details. While some manufacturers feature a rotating saw, making compound cuts or creating intricate inlays and designs are not suitable for this equipment.

CNC Routers and Engraving Machines

These machines can cut more complex shapes, edges and angles utilizing CNC controls, processing materials such as quartz stone, marble, slate, granite, ceramic tile, and many artificial stones. Sometimes referred to as the stone CNC machine, the granite CNC machine, marble CNC machine and quartz CNC machine they utilize bits that come into direct contact with the stone material. As with saw blades, milling bits wear out rapidly, especially cutting harder stone making them more susceptible to accuracy and finish issues across the workpiece.

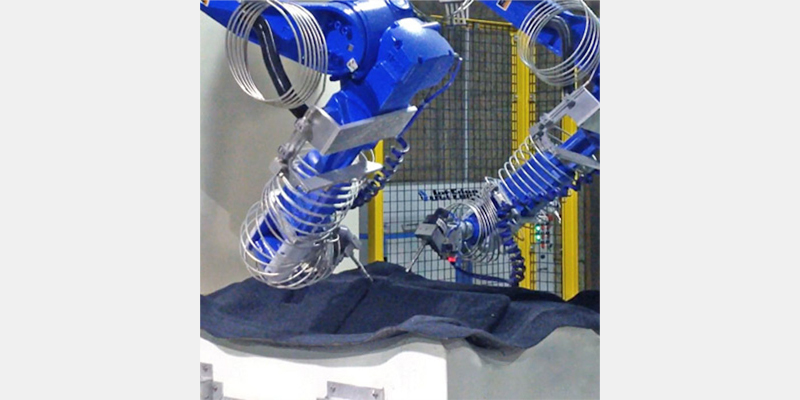

Water Jet Machines and SawJets

Water jet systems utilize high pressure water and a garnet abrasive to cut stone accurately and efficiently. Waterjets have significant advantages over other cutting methods with their CNC controls, 5-axis cutting capabilities, accuracy of cut and ability to handle an incredibly broad array of materials in addition to stone. SawJets, which are a hybrid, system incorporate a circular saw for straight cuts and a waterjet cutting head for piercing, contours and intricate cuts.

Advantages of Cutting Stone with Water Jet Cutting Machines

The waterjet is the most versatile cutting tool available today. No competing technology cuts as many material types in as many thicknesses as a waterjet. And you can include stone in the list of materials waterjets cut with ease and precision. Some key differentiators include:

Vibration, heat and direct contact with a cutting tool are eliminated. Rotating and spinning cutters create vibrations and heat during the cutting process that can cause stock fracturing, damaged edges and create a HAZ. It may seem counterintuitive that stone is susceptible to HAZ, but it is a fabrication risk when cutting certain stone types.

Waterjets are "indifferent" to the type of stone they cut. With an almost infinite number of water pressure levels, grit size and nozzle configuration combinations available to the fabricator, the perfect combination for perfectly cutting any stone is within reach.

The variable thickness that limits competing technologies isn't an issue for waterjets. Where a CNC tool needs surface contact to deliver its cuts and suffers from variable thicknesses, the waterjet is a "stand-off, contactless" cutter, allowing it to cut varying thicknesses of stone with ease.

Fine edge details and complex cuts are readily handled with a waterjet. They also excel in producing a finished edge in a single pass, something alternative technologies cannot match. Typically, saws and CNC cut stone edges require secondary polishing steps, adding cost and time to the production process. Plunge cuts and waterfall edges are another pair of stone-shaping requirements waterjets handle easily.

Thin kerfs and nesting capabilities equip waterjets to deliver near-net material use, even considering inclusions. When using other cutting technologies, the operator may need to work around inclusions and imperfections his tools cannot accommodate. Waterjet cutting reduces kerf size and makes nesting an option for reduced set up and higher material utilization, which makes your job more profitable.

An unavoidable byproduct of stone cutting is dust, exceptionally fine dust potentially exposing employees and work areas to increased safety risk. Using water to cool cutting tools and reduce dust is commonplace, especially with saws. Waterjets are, by their nature, dust-free. You benefit from a cleaner production floor and an integrated water and grit management system.

Blade wear and replacement is another problem waterjets don’t share. Yes, nozzles wear over time but enjoy a longer mean time between replacement (MTBR) than blades.

Talk to Jet Edge

If your company faces stone cutting issues or wants to expand your service offering to include stone, we should talk about how Jet Edge waterjets can help with this and all your material cutting needs. Let us show you how we can reduce your costs and grow your business with a new, more efficient cutting technology, the waterjet.

To learn more about our water jet systems, click here. Our new Hero Pump series is the latest in water jet intensifier pump technology - click here to see why these pumps are the new industry standard workhorse.

Check Out Our Digital Brochure!

Since 1984, Jet Edge has been designing and manufacturing Ultra-High-Pressure Water jet technology that doesn't back down. Our systems are used around the world in a broad range of industries from the world's leading airlines, to automotive, aerospace and industrial manufacturers, and machine job shops.

To learn more about the Jet Edge difference, our water jet motion systems, pumps and much more, click the button "Download Brochure" to get it now!

%20-%20Jet%20Edge%20Waterjets.png)