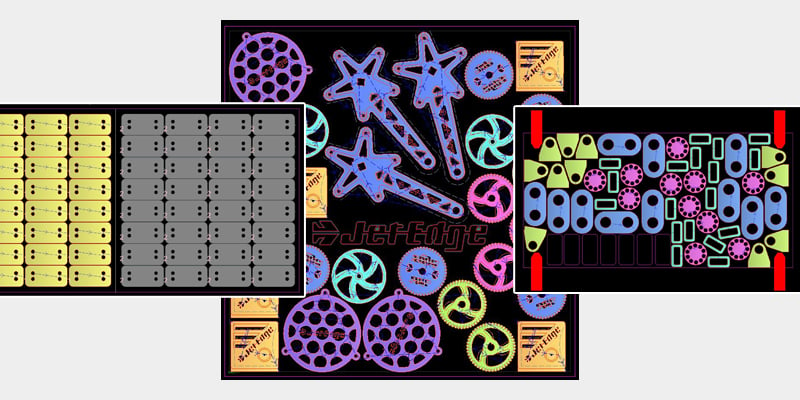

In today’s competitive manufacturing environment, maximizing the value of every sheet of stock material is crucial. That’s where nesting comes in. In water jet cutting applications, nesting utilizes material layout optimization to maximize stock use. Less material goes into the scrap bin, and more profit goes to the bottom line.

This isn’t just a clever layout strategy; it’s one of the most effective ways to reduce cost per part and streamline cutting production. While nesting can be done manually, automated nesting software significantly improves speed, accuracy, and repeatability, especially when integrated with high-precision cutting systems, such as water jets from Jet Edge. In fact, with the thin-kerf capability, thin stock stacking, and the ability to cut any material you can imagine, water jets are the ideal way to integrate nesting into your cutting and machining operations.

Image above shows an example of water jet nesting

Image above shows an example of water jet nesting

The Value of Nesting

Efficient use of material is at the heart of nesting. By laying out as many parts as possible on a given piece of stock, nesting helps reduce scrap, increase overall yield per piece of stock, and control production costs.

This is particularly important when working with high-cost materials, such as aerospace-grade alloys, natural stone slabs, or advanced composites. When your clients require such “exotic” (and expensive) materials, every bit of unused or wasted stock translates directly into increased costs.

Nesting also supports sustainability initiatives and achieving a competitive edge. Shops that can consistently cut more parts from the same or less material than their competitors gain an immediate advantage in customer value, profitability, and reduced environmental impact.

As noted in our blog post for stone fabricators, "What Stone Cutters and Countertop Fabricators Need to Know About Cutting Stone with Water Jet Machines," nesting can result in maximum material utilization, even when working around natural imperfections, such as inclusions.

Manual vs Automated Nesting

Sure, it’s possible for a designer with a lot of experience and a keen eye for layout to manually nest parts for production. But those people are few and far between. However, it is an option, so we’ll take a look at how to perform manual nesting and then dive into automating the effort.

Manual Nesting

Manual nesting involves positioning and orienting parts by hand within CAD/CAM software. While it allows for total human control, it is also time-intensive, prone to inconsistency, and highly dependent on the technician's skill and experience. It also ranks low for repeatability if the CAD/CAM file becomes lost or corrupted.

Automated Nesting

By contrast, automated nesting software uses sophisticated algorithms rather than older methods to generate layouts that optimize material usage quickly. Automated layout:

- Reduces setup time, which is valuable when engaged in just-in-time manufacturing

- Ensures repeatable, accurate layouts, especially useful in short-run jobs

- Minimizes waste and machine travel time

- Lowers the risk of operator error

For even greater benefits, pairing nesting with common line cutting, a technique where adjacent parts share an edge, further increases material utilization and reduces cutting time. You can read more about combining these two techniques in our post on improving productivity, How to Maximize Abrasive Cutting Productivity.”

How Nesting Software Works

At its core, nesting software imports part geometry from CAD files and arranges them on a virtual sheet of material for optimal yield. Advanced features in systems like IGEMS CAD/CAM software (Jet Edge deploys IGEMS on all its machines and is required for 5-axis cutting with Jet Edge equipment):

- Array nesting for repeated part layouts

- Part rotation to fit shapes more efficiently

- Collision avoidance to protect parts and tooling

- Toolpath optimization to reduce cutting head travel distance

- Remnant reuse, which allows shops to cut small parts from leftover material

- Part in part nesting, which allow smaller parts to be nested inside of larger drops to utilize the most material.

These features are not only practical, they’re essential to modern, high-efficiency cutting operations.

According to the Society of Manufacturing Engineers (SME), integrating CAD/CAM with automated nesting and material tracking systems contributes to better resource planning and improved lean manufacturing outcomes (SME Smart Manufacturing report, 2020).

Benefits of Using Advanced Nesting Software

Here are the top benefits you’ll enjoy when you integrate nesting software into your operations:

- Material Efficiency – Cut more parts from every sheet.

- Reduced Cost Per Part – Less waste means lower material and operational costs.

- Increased Productivity – Optimized layouts lead to faster cutting cycles and fewer total cutting operations.

- Ease of Use – Intuitive interfaces reduce learning curves for new operators.

- Flexibility – Accommodates multiple part geometries, quantities, and production goals.

Jet Edge integrates IGEMS software with our water jet cutting systems. This proven package is widely regarded as the best nesting solution for CNC water jet cutting machine tools. We explain in more detail how this pairing of water jets, IGEMS, and nesting enables operators to lay out the most complex part geometries with confidence and consistency in our blog post, "How Water Jet Control Systems Impact Cut Quality.”

Best Practices for Effective Nesting

To get the most out of your nesting process, we recommend following these practices:

- Use clean CAD files: Simplified geometry helps software generate more efficient nests. Most pieces of CAM software have a clean-up function built in (including IGEMS).

- Tight spacing: Maximize material use while allowing for safe kerf width and lead-ins.

- Lead-in/lead-out planning: Avoid material deformation or edge irregularities. Best practice is to place tool path on parts after nesting on sheet

- Save your remnants: The remnants should be saved in the CAD/CAM software as a sheet for easily pulling the remnant up for jobs. They can be nested with smaller parts in future jobs. (In IGEMS this is done in the Sheet Database)

- Update software regularly: Stay current with algorithm improvements and features.

- Plan for hold down clamps/fixtures: Placing the location of the clamps before nesting will lead to quicker setup time for the operator, and minimize confusion on where they can clamp

The Fabricators & Manufacturers Association (FMA) emphasizes that regularly updated software contributes significantly to improved material efficiency and production consistency (FMA Best Practices Guide, 2021). In addition to these benefits, current software reduces the threat from malware and viruses, a problem that is becoming increasingly prevalent in commercial and industrial manufacturing systems.

Conclusion

Nesting isn’t just about layouts; it’s a strategic move that improves profitability, sustainability, and throughput in water jet cutting operations. Shops that adopt automated nesting tools, particularly those that integrate seamlessly with high-performance systems like Jet Edge, gain a measurable competitive edge. From reduced material waste to faster cycle times, the benefits speak for themselves.

If you're interesting in learning more about how Jet Edge systems utilize nesting, contact us today to learn how to increase the services you offer your customers and reduce costs through enhanced productivity. You can also call us toll-free at 1-800-JET-EDGE (538-3343), internationally at +1-763-497-8700 or visit our website jetedgewaterjets.com to learn more.

Check Out Our Digital Brochure!

Since 1984, Jet Edge has been designing and manufacturing Ultra-High-Pressure Water jet technology that doesn't back down. Our systems are used around the world in a broad range of industries from the world's leading airlines, to automotive, aerospace and industrial manufacturers, and machine job shops.

To learn more about the Jet Edge difference, our water jet motion systems, pumps and much more, click the button "Download Brochure" to get it now!

%20-%20Jet%20Edge%20Waterjets.png)