For as long as we’ve been around, Jet Edge has been dedicated to educating end-users of water jet cutting systems regardless of the manufacturer. One of the most significant parts of that dedication to continued education is proper maintenance of water jet systems and their associated high-pressure pumps.

Proper maintenance intervals for your equipment leads to significantly longer component and machine life and better performance during operation. If you are currently using a water jet cutting system, then you know that downtime is a revenue killer. Proper maintenance on your system leads to higher productivity and significantly less downtime.

In this post, the first in a three-part pump maintenance series, we’ll be going through the maintenance of the pump accumulator. By checking and maintaining the accumulator pressure, you’ll keep your high-pressure pump running at top performance for significant periods of time.

Check out the full video guide to maintaining your accumulator by clicking the video below:

What is a Pump Accumulator?

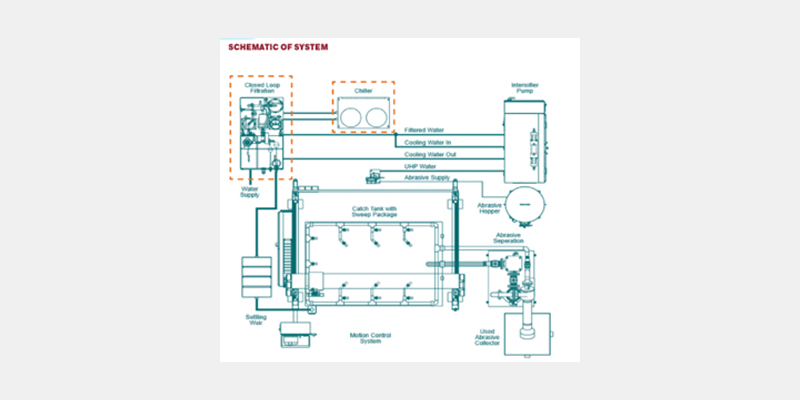

The high-pressure pump accumulator, or hydraulic accumulator, is a high-pressure storage device. In high-pressure water cutting systems, it reduces the overall shock in the intensifier pump hydraulic system. This in turn improves overall performance of the hydraulic and the high pressure water systems in your pump.

To properly maintain you pump, the accumulator’s pressure needs to be checked monthly, and if needed, charged.

How Do I Know When to Charge My Accumulator?

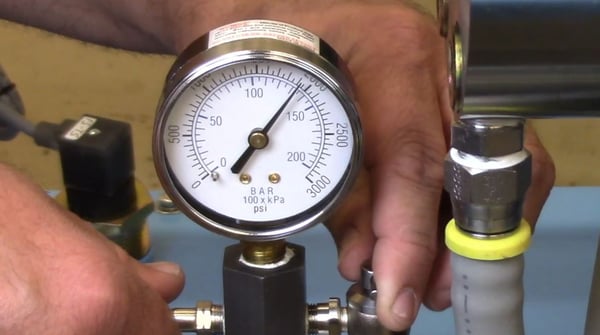

The rule that governs when an accumulator needs maintenance is when it is 10% off its charged pressure rating. Generally speaking, this is when the pressure is 10% less than the charged rating. However, there are times when pressure is 10% too high and needs to be bled until at the appropriate rating.

The rated pressure of your accumulator depends on the manufacturer of the pump, and varies from model to model, so be sure to check your pump owner’s manual for the proper rating before performing maintenance.

On Jet Edge models, the main pressure accumulator is charged to 1,750 PSI, the return accumulator rating is 30 PSI, and the ramping accumulator is 750 PSI. Be sure to check all the accumulators in your system during maintenance.

Maintaining Your Accumulator

Tools needed for this maintenance:

- Accumulator charging kit (Jet Edge part number 28599)

- This includes:

- 3,000 PSI 200 bar high-pressure gauge (for high pressure accumulators)

- 600 PSI 40 bar low-pressure gauge (for return accumulator)

- This includes:

- Adjustable wrench

- Tank of dry nitrogen charged to at least 1,800 PSI for proper recharging

Steps to Complete

- Checking Accumulator Charge Level

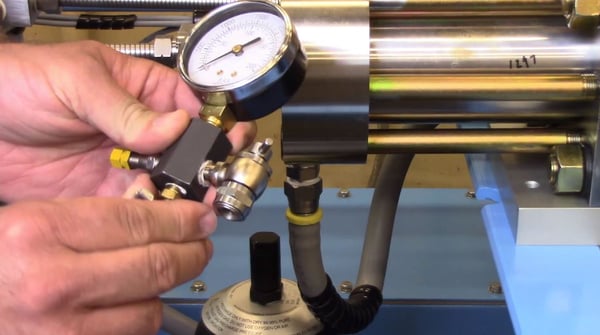

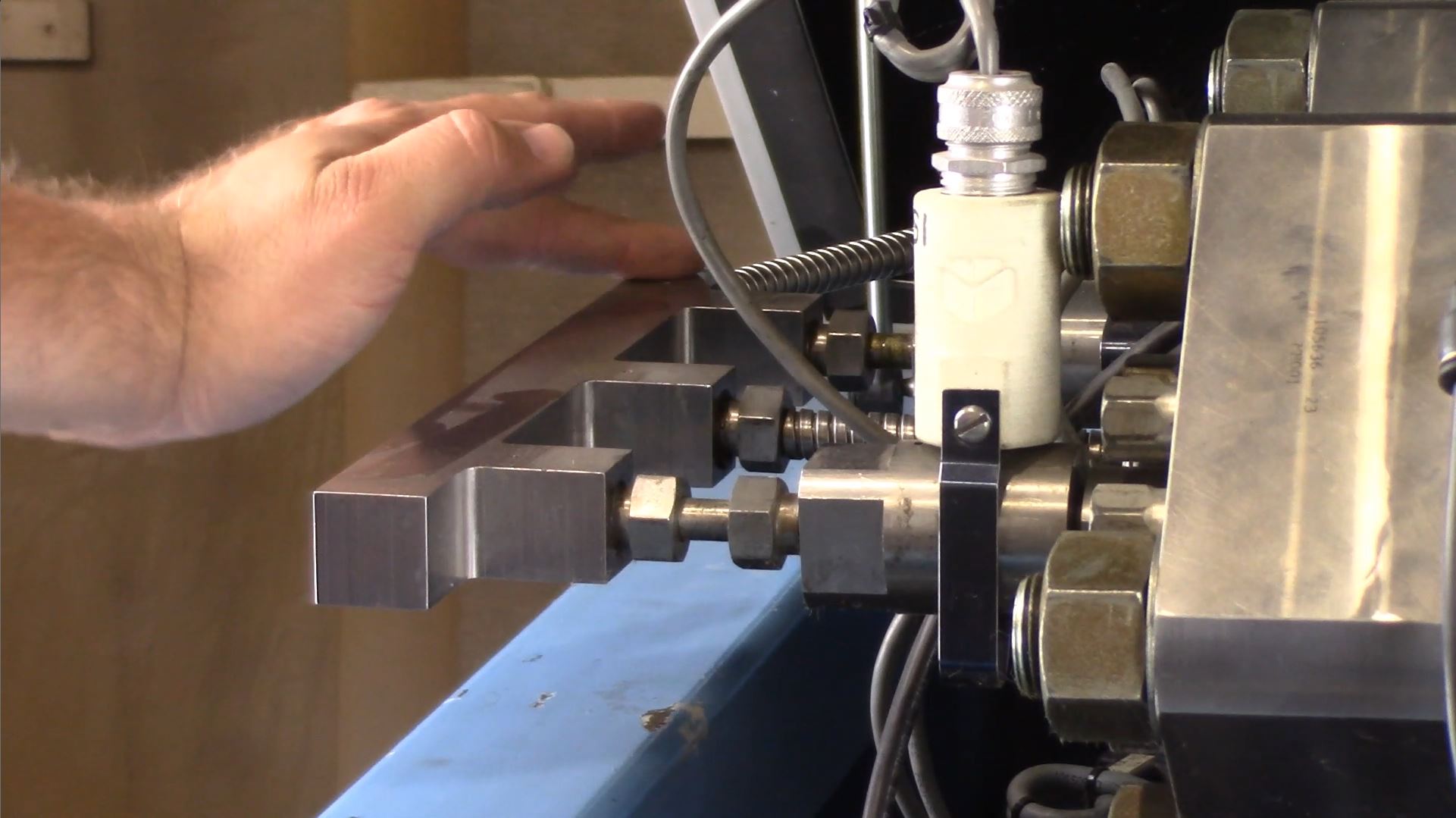

- Before attaching the actuator to the accumulator, make sure the actuator needle is turned fully counterclockwise and the bleed valve is turned fully clockwise

- Remove the valve cap from the accumulator and stem cap from the accumulator

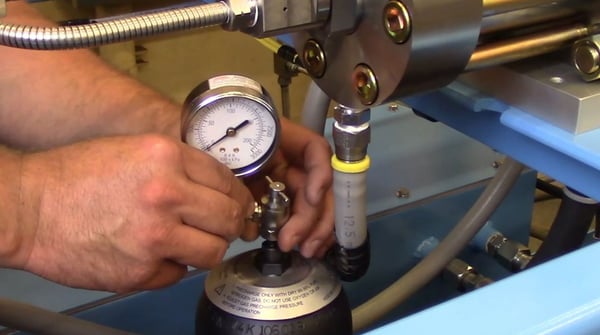

- Thread the actuator assembly to the valve on the accumulator and use the adjustable wrench to secure the assembly

- Turn the needle actuator on the gauge slowly clockwise and observe the pressure reading. If the actuator is more than 10% below proper charge pressure, it needs to be charged

- Before attaching the actuator to the accumulator, make sure the actuator needle is turned fully counterclockwise and the bleed valve is turned fully clockwise

- Charging the Accumulator

- Using the tank of dry nitrogen, remove the port covers to expose the hose

- Install the adapter hose to the gauge head assembly and the nitrogen supply tank, use the adjustable wrench as needed to fully secure the hose to the supply tank.

- Slowly open the valve on the nitrogen supply while observing the gauge reading, when the gauge reading is proper, turn the valve off and check the gauge reading. Repeat until pressure is adequate

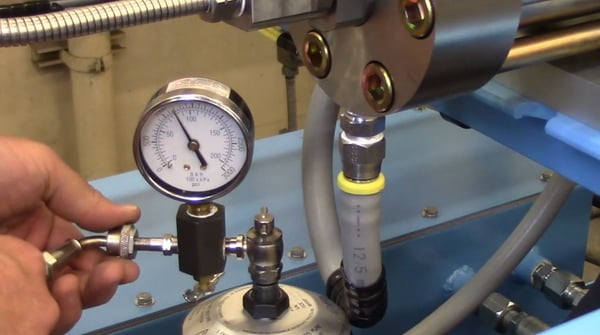

- When this is complete, verify the valve on the nitrogen supply tank is fully closed, turn the needle actuator fully counterclockwise

- Turn the bleed valve slowly clockwise to relieve any line pressure

- Remove the charging hose from the gauge assembly and nitrogen supply tank

- Use the adjustable wrench to remove the gauge assembly from the accumulator

- Reinstall stem cap and cover cap on the accumulator

- The machine is now ready for use

Check Out Our Digital Brochure!

Since 1984, Jet Edge has been designing and manufacturing Ultra-High-Pressure Water jet technology that doesn't back down. Our systems are used around the world in a broad range of industries from the world's leading airlines, to automotive, aerospace and industrial manufacturers, and machine job shops.

To learn more about the Jet Edge difference, our water jet motion systems, pumps and much more, click the button "Download Brochure" to get it now!

%20-%20Jet%20Edge%20Waterjets.png)