Water jet cutting systems are high-precision tools engineered to produce the most complex cuts with the best first-cut edge finish in the largest number of materials. The old saying, “the whole is greater than the sum of its parts,” definitely describes water jets. Yet, the quality and characteristics of each part impact how much greater the sum will be. Change the quality of a part, and the sum (performance in cutting systems) changes.

Where are we going with this analogy? You can buy water jet parts from an OEM, aftermarket, or remanufactured provider when replacing a part - but which option will have the least impact on the performance of your water jet? Let’s explore.

OEM or Aftermarket Parts - Which Should You Choose?

Complex products commonly have aftermarket parts available. Aftermarket parts sellers thrive on creating “clones” of their OEM counterparts and selling them for less than the originals. Aftermarket parts work well in specific applications like automotive. But are they suitable for water jets that rely on extreme precision and stringent quality control (QC) levels to perform at their best? Let’s look at the pros and cons of each, starting with OEM.

OEM Water Jet Parts - Advantages

The advantages of OEM parts are obvious; no one knows how to make the part better than the company that engineers and manufactures it. These companies have the technical drawings, manufacturing specifications, CAD files, materials, and tooling (if required) for the original part. Here are the advantages of replacing your parts with OEM.

- Quality – OEM manufacturers tend to have higher QC standards and practices.

- Compatibility – You know the OEM part will work with your specific water jet model.

- Warranty – OEM parts typically have better warranty coverage than their OEM equivalent and exercising warranty claims should a part fail may be easier. Make sure you read your OEM’s warranty policy carefully to make sure the equipment warranty is not voided by using aftermarket parts.

- Support – The OEM knows their equipment more intimately and has all of the technical documentation for the equipment sold to you. With the OEM, you will get both the part you need and the support required to install it. Visit our MyEquipment page at Jet Edge to see how that technical support is shared with users.

- Recommended Service Intervals – The OEM often produces service schedules that recommend when service should take place. That predictive maintenance data is based on the assumption OEM parts are used and these intervals may not apply to aftermarket parts.

- Longevity and durability – The quality of materials and manufacturing precision runs higher in OEM environments, enabling the OEM part to last longer than the aftermarket offering.

- Performance consistent with the previous part – You are replacing like for like, ensuring the performance of the part and your water jet will be the same as before the part replacement.

An uncomplicated way to summarize the benefits of an OEM part is this, “No surprises.” You know it will fit and perform just like the original that came with the water jet.

OEM Water Jet Parts - Disadvantages

It’s hard to ignore the advantages of an OEM replacement part. But, the option does have its disadvantages, which include the following:

- Higher cost – This may be the most common criticism of an OEM part; they cost more because delivering the above benefits is more expensive.

- After Market parts variety – OEMs generally recommend a narrow product offering that they feel optimizes their equipment performance. After Market suppliers are not constrained and can adapt parts or equipment with additional features the buyer may find value with.

- EOL and obsolete equipment parts unavailable – OEMs commonly make a final run of parts for equipment at its end of life (EOL). Once they are gone, the company will not make more. Auction sites may be the final place to source out of service OEM parts.

Aftermarket Water Jet Parts - Advantages

Now, it’s time to dive into the pros and cons of aftermarket parts. What sets the aftermarket option apart?

- Lower pricing – Since aftermarket companies do not boast the above advantages of the OEM, they rely on pricing as their primary differentiator. Since many of the aftermarket distributors do not have the overhead OEM’s do with engineering, R&D, production, complex supply chains, etc. they can afford to accept lower margins. They may also rely on foreign sourced components in low wage countries that use lower quality materials. For more information on this, see our blog about the importance of Made in America.

- Faster availability – For aftermarket companies, parts are their business, and they can’t make any money if they don’t have parts to sell. Therefore, these companies may try to maintain higher inventory levels or arrange drop shipments directly from their supplier source. Also, since there are more of them, you may be able to shop multiple aftermarket companies to find the part you are looking for.

- Performance options – Aftermarket companies are not limited to a single OEM and may offer components from other suppliers that they feel perform better in a specific application than the OEM’s solution. They may also offer additional application accessories supplied from other 3rd parties that the user may find value in.

Aftermarket Water Jet Parts - Disadvantages

Aftermarket parts do suffer from an entrenched view they are not and never will be as good as the OEM supplied product. Some of those disadvantages, include:

- Limited product offering – The aftermarket distributor can never expect to carry the full range of components the OEM can. So, they tend to focus on a narrow range of components that are easier to source, lower in cost and turn more frequently.

- Incompatibility – Parts change over the life of an asset as products are enhanced. The aftermarket supplier does not have access to the engineering documentation and will always be slow to “copy” the new designs.

- Patents – Many OEM technologies are patented upon release. The aftermarket part must be different enough from the OEM to avoid patent infringement legal issues. As a result, when you buy an aftermarket part, you risk it not being perfectly compatible with your water jet.

- Quality concerns – Aftermarket companies primarily rely on pricing and must find ways to reduce the cost of producing their products. Foreign sourcing, lower-quality materials, incomplete assemblies, and other corner cutting may reduce quality.

- Warranty – Aftermarket part warranties rarely match the protection of an OEM warranty. And, for overseas aftermarket companies, exercising and receiving satisfaction on a warranty claim can be challenging.

- Support – Let’s face it: the OEM for your water jet is not likely to offer help when you have an issue resulting from using an aftermarket part. That means you must carefully investigate your aftermarket supplier's support capabilities and reputation before buying your part.

- Longevity and durability – A lower-quality part rarely performs as long and reliably as an OEM one. That means you face more frequent maintenance and replacement, incurring costs that erode the price savings.

Remanufactured Assemblies - A Middle Ground

In certain instances, you may find remanufactured assemblies are available. The remanufacturer disassembles the old assembly, thoroughly cleans the parts, replaces worn and broken components, and tests it to ensure proper operation. What are the pros and cons of this option?

Remanufactured Assemblies - Advantages

Who performs the remanufacturing impacts its conformance to the OEM supplier. Ask if OEM parts are used or whether aftermarket parts are used on the rebuild.

- Price and compatibility - The remanufactured assembly will cost less since many of the assemblies most expensive components are reused. Compatibility should be high, especially if OEM parts are used.

- Availability of current and obsolete parts – As long as the remanufacturer has a reliable source of used products, they can build a more extensive inventory than most OEMs, enabling faster delivery. They can also be an excellent source of obsolete parts.

- Environmental impact – Remanufactured parts are the greenest option because they reuse materials already processed for the original part and prevent valuable resources from hitting landfills.

Remanufactured Assemblies - Disadvantages

Remanufactured assemblies in some instances are the only cost effective or viable option. However, be aware of potential issues.

- Quality, durability, and longevity – Many of the components in a remanufactured assembly are not replaced so you are starting with a used platform. If the remanufacturer skimps on the quality of replacement components and their rebuilding process, the parts replaced may fail or the parts not replaced may fail much sooner than a new assembly.

- Warranty – Like the aftermarket option, warranties on remanufactured items typically are not as extensive as an OEM offers, and exercising warranty claims may be difficult. Researching the vendor’s reputation for backing their products is vital.

- Support – You may have better luck getting help from your water jet’s manufacturer if they did the remanufacturing. However, it’s best to research the support the remanufacturer provides.

Choosing the Option that Best Meets Your Needs

Most every OEM would begrudgingly concede there is a place for aftermarket suppliers. In fact, at Jet Edge, we use our engineering expertise to offer competitor aftermarket components through our sister company Choice Water jet Parts. Visit ChoiceWater jetParts.com to see the range of water jet equipment providers we support.

So how do we suggest you walk the line between OEM suppliers and aftermarket suppliers? Look at your requirements.

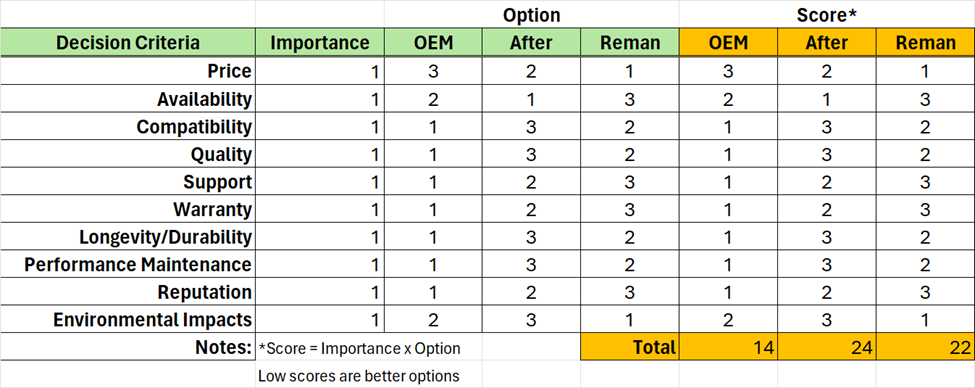

Decision Matrix

With all decision matrices, the primary decision criteria is ranked by importance and evaluated across the range of options. Be discerning with your importance rank. If you rank quality too low and price too high, you may end up producing at a scrap rate that dwarfs the cost savings realized with cheaper components.

With this simple 1, 2, and 3 option weighting scale, 1 being the most important, you contrast the value between sourcing options. The lowest score directs you to the preferred supplier.

Talk to Jet Edge About Your Replacement Part Needs

We encourage you to call us first whenever you need to replace a part. One of our engineers will gladly discuss your situation and needs. Together, we’ll work to ensure you have all the information necessary to choose the option that best meets your needs.

Check Out Our Digital Brochure!

Since 1984, Jet Edge has been designing and manufacturing Ultra-High-Pressure Water jet technology that doesn't back down. Our systems are used around the world in a broad range of industries from the world's leading airlines, to automotive, aerospace and industrial manufacturers, and machine job shops.

To learn more about the Jet Edge difference, our water jet motion systems, pumps and much more, click the button "Download Brochure" to get it now!

%20-%20Jet%20Edge%20Waterjets.png)